Our services

Together with our customers to new material top performances

New composite materials

for your requirements

Innovative plating of multiple materials (including plastic, metal, ceramics) at nano & micro level for better material properties.

Powder modification

In powder modification, metal, ceramic, plastic or cement particles are coated with other, smaller particles in the powder. This procedure offers many possibilities for material optimisation. Physical properties of components or coatings can be specifically adjusted or changed in this way.

We offer:

- Production of powders with modified properties

- Material combination as required

- Determination of characteristic values

- Powder for coatings

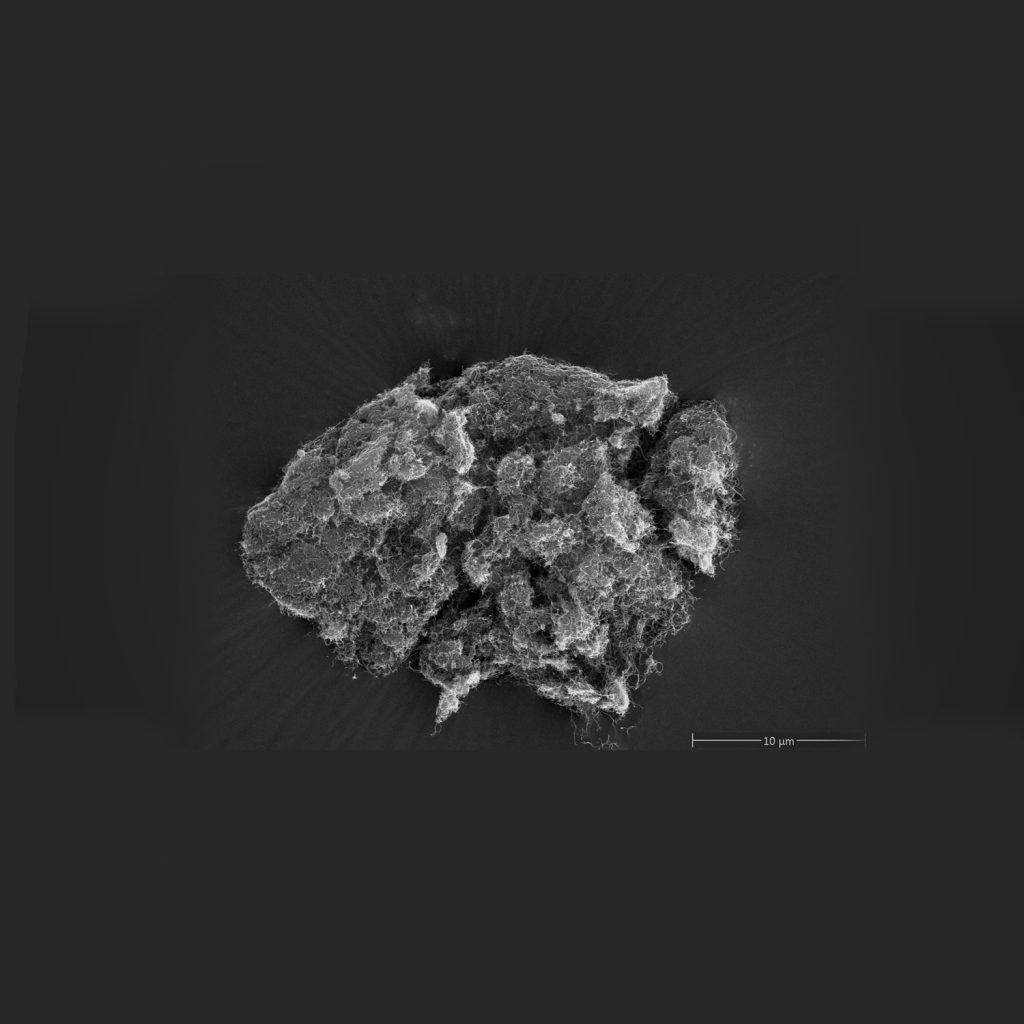

Micro and nano powders

The production of micro- and nanopowders from various materials is a prerequisite for many technical applications. NanoFract uses in-house developed technologies to produce fine micropowders from PE plastics, among other materials. This enables us to adapt the particle sizes to the wishes of our customers.

We offer:

- Production of micro- and nanopowders from desired materials (up to 100 nm)

- Plastic comminution

- Fine grinding of metals, cement and ceramics

- Technical testing as required

Powder for cold gas spraying

We are supplier of powders for cold gas spraying. In cooperation with our partner MBL Systems GmbH, we develop individual solutions to enable component repair with complex geometries and material compositions.

Examples of materials

– stainless steel

– tool steel

– Aluminum

– Brass

– Glas-Metal Composites

Granular coating

In order to specifically adapt the properties of the materials to customer requirements, we coat granulate with other materials. In this way, a wide variety of material combinations can be adapted to the requirements for injection moulding and extrusion.

We offer:

- Coating of granulates (1 mm to 15 mm)

- Nanomodification of granulate surfaces

- Micromodification of granulate surfaces by other materials

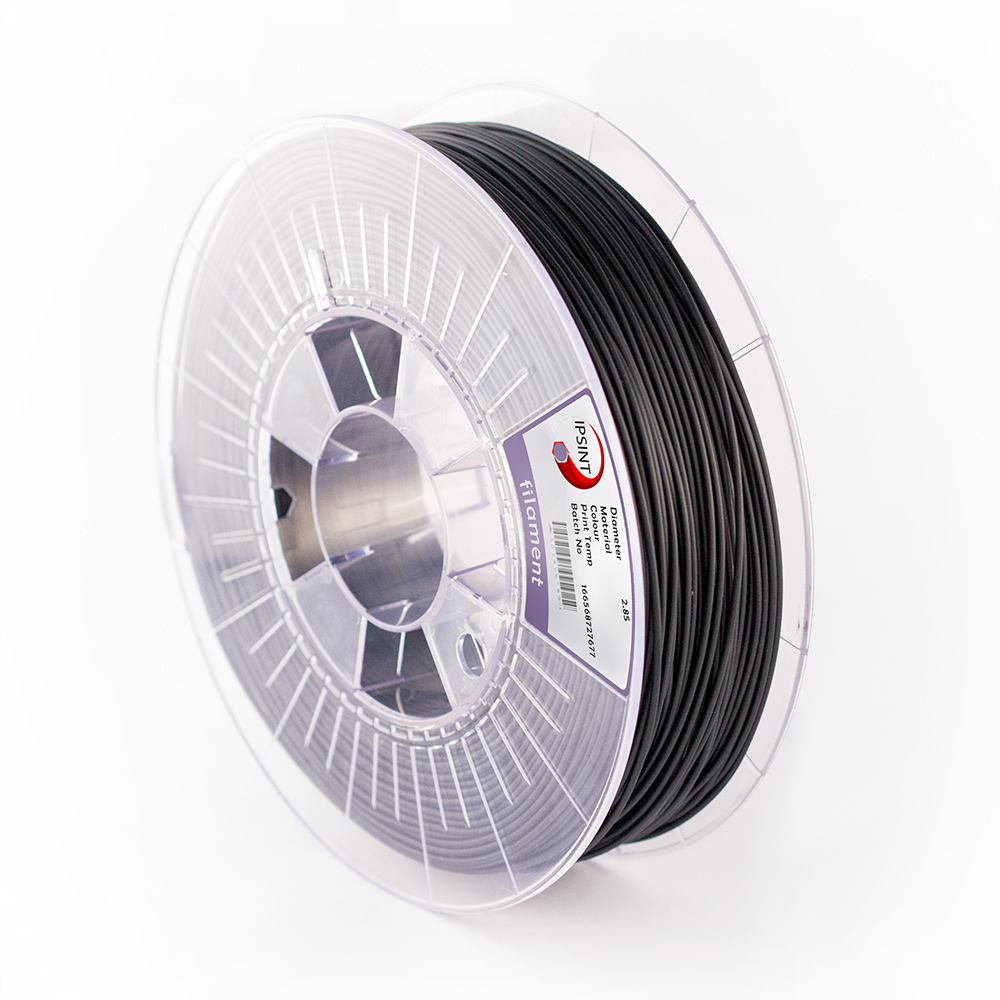

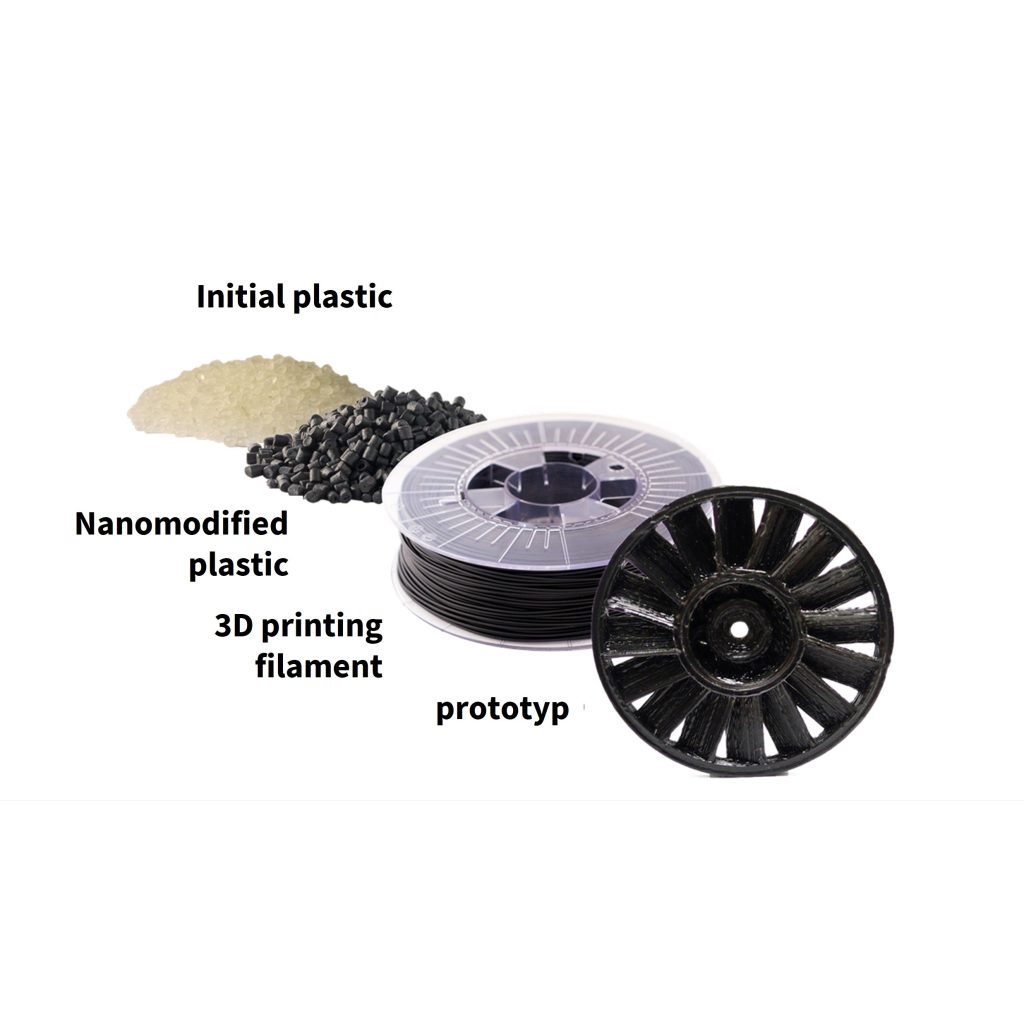

Filament

We extrude our materials into filament for our customers. In cooperation with our partners, we are also able to serve large customers. An extrusion of metallic FDM filament is possible after consultation.

We offer:

- Extrusion of modified plastics

- Extrusion of metallic FDM filament

- Colour combinations on customer request

FEM calculation

NanoFract accompanies its customers from the very beginning. Among other services, we offer the constructive design as well as FEM calculations of components with the desired materials. Through our experience in the fields of process engineering, we have specialised in the finite element method calculation of fluid mechanics and particle movements. Together with the customer, we develop initial requirements and specifications and carry out the corresponding design.

We offer:

- Construction

- CFD simulation incl. particle simulation

- Structural mechanics incl. lifetime calculation

- Coupling of several physics interfaces

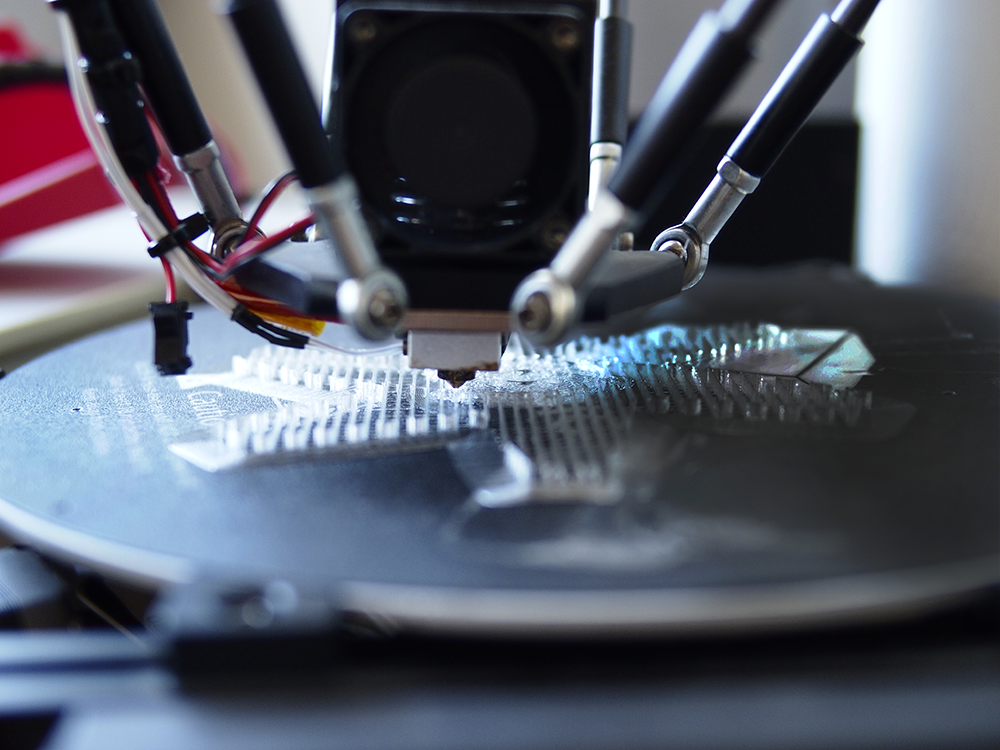

3D printing

In order to be able to support our customers in the best possible way, we offer our 3D printing service to accompany our material developments. Prototype parts can be printed directly from our materials on request.

We offer:

- 3D printing up to 200 x 200 x 200 mm

- High temperature plastics (up to 450°C)

- manufacturing component optimization

Satisfied Customers